All the valves need taking out and clearances checked.

Welcome to my 1983 GS1100 G Restoration Project. This bike has been in my family since new. It was bought by my Dad new in 1985 in Ontario, Canada. He toured the US with it with my Mum on the back (both have since passed away). I imported it into the UK around 1996 and rode it around London for a couple of years. Then it sat in the garden for 10 yrs (oh the horror!). Now: RESTORATION. Please use contact form page for comments. Click on photos to enlarge. Project started 18th August, 2012.

Saturday, 5 November 2016

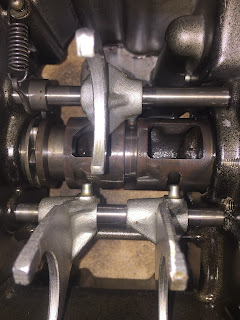

Gear Box Components Out

For vapour blasting all the internals need to come out.

Including this roller bearing that supports the gear selector drum.

Labels:

dismantling,

engine

And How Are Things Inside?

Quick look at the pistons: they have very few marks on their side but are quite sooty. I guess they were quite carbonned up, even though the mileage wasn't high. I sprayed WD40 into the barrels several times over the years to stop any corrosion and that's a good way to loosen up the deposits. They are very soft now.

To get the crank out it was necessary to take off pistons 1 and 4.

Labels:

dismantling,

engine

Cases Ahoy!

Now to get the cases apart and not to forget all the bolts top and bottom and the retaining plate clutch side. (Click on images to enlarge)

Labels:

dismantling,

engine

Sunday, 9 October 2016

Sump Comes Off

Lets see what's happening in the sump - always tells you what's been going on in the engine:

There was a little bit of gunk in the bottom - nothing to worry about considering this motor has been idle for at least 15 years.

And with the filter, I took the mesh off and there was nothing in it at all.

Labels:

dismantling,

engine

Barrel Off

Head came off easily but the barrel didn't want to move. Lots of gentle knock with bits of wood and even a bit of levering.

Ready for taking to the vapour blaster.

Labels:

dismantling,

engine

Head Off (1,523 Days into the project - how bad is that?)

Got the head off. I was very surprised at the carbon build up on the pistons and combustion chamber for such a low mileage motor.

Honing still visible:

But the cam chain guides show very little wear:

Labels:

dismantling,

engine

Subscribe to:

Comments (Atom)