Here is a bit more of the technical explanation of how I got the engine out. (The video of the whole affair is here: Engine Removal Video in a previous post).

Actually saying that this is a technical explanation is really a lie. There was nothing really technical about what we did. Brute force, a hacksaw and plenty of help is what is needed.

Let me first show you what we were supposed to do (in reverse order of course). All well and good if you have the engine hoist, a scissor platform jack and a car axle jack just lying around. That's about £1,000 worth of equipment in my neck of the woods. But I did have a laugh when I saw these photos. This is USA vs Rest of the World analogy. You guys (from the USA) have so much (just look at the amount of land there is surrounding this engine!) you don't even know you are alive! We are paying $8.39 per US gallon of gas compared to the $3.15 or so that you pay. Nearly 3 times your amount. So look at the equipment here:

Nice looking engine BTW.

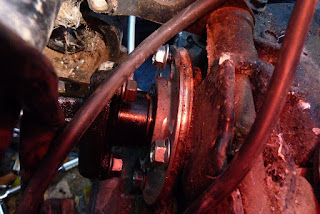

With all the bolts removed, we shook and pried at the engine. But it would still not come out. With 3 of us lifting the frame (complete with forks and rear swing arm) we were rapidly running out of energy. I took off the swing arm again to make it lighter. And finally...

The workshop manual is not much help (click on the photo to enlarge) saying simply: "gradually lift up engine and lower". Don't try this at home children.

I eventually got the shaft drive off the engine (see previous post). Then we put the rear swing arm back on so we could wheel it into the garden. It was a tough job because both the tyres are flat and the front wheel is virtually seized.

We layed it down on the grass. Then I removed the last bolts. Then we discovered that I had not disconected the tacho cable. I tried getting it off with a clamp wrench not realising that I needed to remove a cross headed screw first. By now it was dark and I couldn't see it. And if the truth was known, I had not consulted to the workshop manual about this.

With all the bolts removed, we shook and pried at the engine. But it would still not come out. With 3 of us lifting the frame (complete with forks and rear swing arm) we were rapidly running out of energy. I took off the swing arm again to make it lighter. And finally...